Sectional Warping Machine Calculation

If the net weight of the warp on the beam is 663 lbs calculate the beam count.

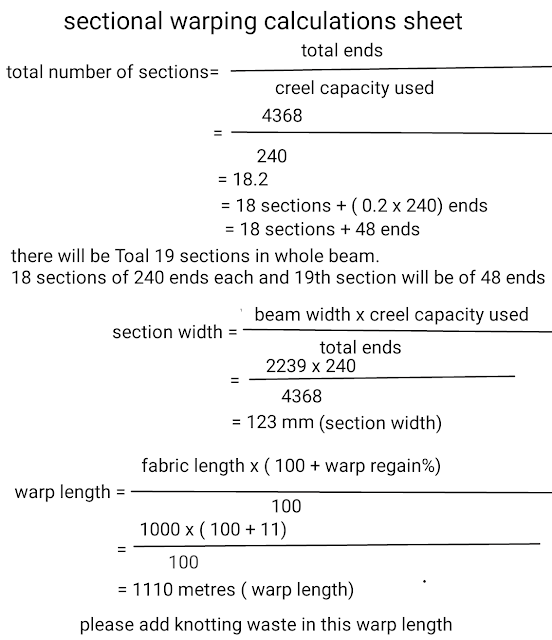

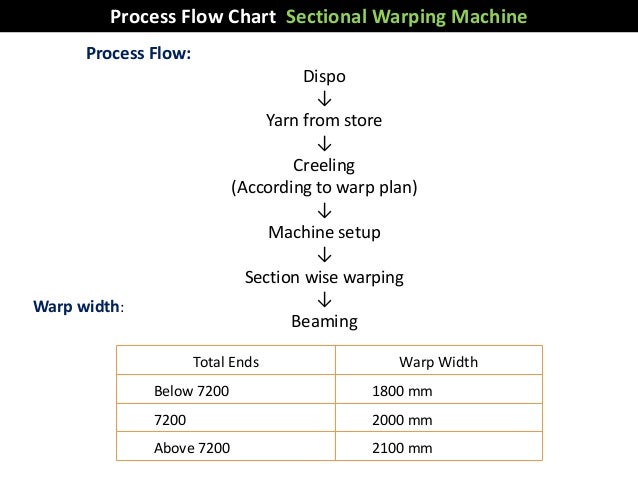

Sectional warping machine calculation. Sectional warping is one of the important processes of textile weaving where equal length of yarn is wound first in small sheets or sections on a drum. Of ends per pattern 42 so no. This type of warping is a two stage process which is used to produce fancy fabrics by using color and weave effect.

A typical calculation for sectional warping. Sectional warping is also known as pattern. Total length of yarn in warp length of warp number of ends.

Generally sectional warping is used to make weaver s beams of multi plies yarn. The fabric parameters required to make a beam on sectional warping machine are given below. Academia edu is a platform for academics to share research papers.

H creels are used in sectional warping. A warper s beam produced on an improved modern high speed beam warping machine contains 39780 yds of warp with 420 ends. The package holder slub catcher tensioner and compensator are the important parts of the creel 3 4.

Sectional warping creels are different from direct warping creels mainly in terms of creels capacity. Fabric width 84 inches. Design and capacity of the creel governs the efficiency and product quality of the warping machine.

After that it is transferred to the beam from the drum in the form of a sheet.